|

Phoenix Microelectronics, Inc. |

|

The Best Assembly Anywhere |

|

Quality |

|

Quality and for success, and our commitment to quality assurance is the thrust behind everything we do. From the smallest grain of sand to the finished item, Phoenix is dedicated to creating products that consistently meet or exceed the expectations of our customers, regardless of the size or scope of their production needs. |

Our hallmark and drive |

|

Phoenix Microelectronics Quality |

|

At Phoenix, we optimize value through rigorous quality programs, which are controlled by the Phoenix Quality Assurance Manual. Phoenix assures the integrity of all the products we manufacture through the implementation of a quality system in supporting ISO 9001:2000 requirements. The hybrid microcircuit general specification (MIL-PRF-38534) is also used for process control, traceability, rework and screening. |

|

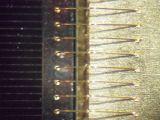

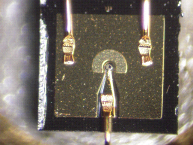

Phoenix Quality Assurance organization ensures that quality is recognized and implemented during the earliest phases of program planning, product design, product manufacturing and customer service. Numerous in-process steps are taken to verify that hybrids are produced under control at all times. These checks include wire bond strength testing, die shear testing, and "Gold Standard" electrical testing, verifying that our final electrical test equipment always meets the required performance criteria. The Quality Assurance function is implemented by a dedicated Quality Assurance Manager who interfaces with program management and the customer to define and document quality requirements and verify compliance at every conceivable stage of production. |

|

Phoenix Delivers: |

|

· Rapid time to Market for your prototype · Rapid time to Volume for your production needs · Rapid time to Cost for your bottom line |

|

Testing: |

|

Phoenix burn-in capabilities include: · MIL-STD-883 · Capacity-package Dependant |

|

Environmental Screening |

|

Phoenix Test capabilities include: · IEEE 488, Rack and Stack · HP 3060A (variable Temperature) |

|

Burn In |

|

Phoenix screening capabilities are per MIL-STD-883. Test methods are as follows: |

|

· Stabilization Bake · Temperature Cycle · Acceleration · PIND · Hermeticity (helium or leak test) |